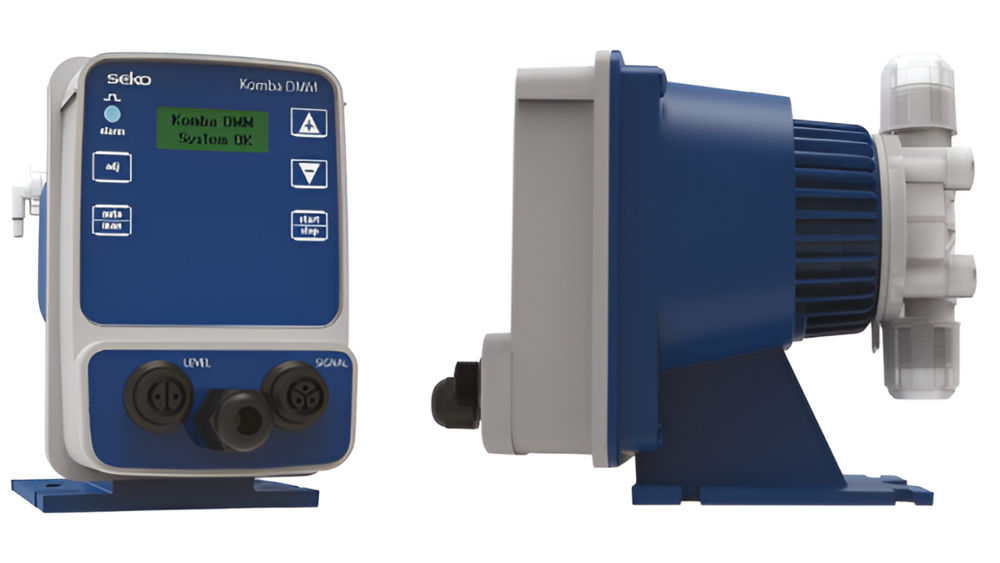

SEKO Solenoid Dosing Pump

SEKO Solenoid Dosing Pump Specification

- Theory

- Electromagnetic Solenoid Driven

- Control System

- Manual stroke length adjustment

- Head Size

- Max 7 bar

- Working Temperature

- 5C to 45C

- Inlet/Outlet

- 68 mm PVC tubing

- Caliber

- 6 mm

- Discharge Pressure

- Up to 7 bar

- Features

- PTFE diaphragm, corrosion-resistant, IP65 enclosure

- Max Suction

- 1.5 meters (dry suction lift)

- Flow Rate

- 0 to 5 LPH (adjustable)

- Mounting Type

- Wall mount or surface mount

- Speed

- Stroke frequency adjustable

- Frequency

- 50/60 Hz

- Voltage

- 230V AC, 50/60 Hz

- Noise Level

- Low

- Material

- PP (Polypropylene) pump head, Viton/EPDM seals, ceramic ball

- Structure

- Wall mounted, compact design

- Power

- 25W

- Standard

- IP65 protection

- Fuel Type

- Electric

- Pressure

- 0 to 7 bar

- Usage

- Chemical dosing, water treatment

- Application

- Water treatment plants, chemical dosing, RO plants, ETP/STP

- Suction Type

- Self-priming

- Seals Type

- PTFE diaphragm

- Priming

- Manual priming

- Pump Type

- Solenoid Dosing Pump

- Capacity

- 0-5 LPH

- Enclosure Rating

- IP65 Weatherproof

- Installation Kit

- All installation accessories included

- Accuracy

- ±2% on repeatability

- Maintenance

- Tool-free diaphragm replacement

- Dimensions

- 185mm x 145mm x 115mm (L x W x H)

- Weight

- Approx. 2.1 kg

- Priming Function

- Equipped with integrated priming valve

- Input Signal

- Manual control (optional external input on select models)

- Display Type

- LED indication for power/dosing

SEKO Solenoid Dosing Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

About SEKO Solenoid Dosing Pump

Types of Solenoids in Pumps:

- Direct-Acting Solenoid: Directly controls the valve's movement with the solenoid. These are used for smaller valves where the solenoid's magnetic field can move the valve without assistance.

-

- Pilot-Operated Solenoid: Uses the solenoid to control a smaller pilot valve, which then operates a larger valve. This is often used in systems requiring higher pressure or flow rates.

Superior Precision and Reliability

Engineered with advanced electromagnetic solenoid technology, the SEKO Solenoid Dosing Pump achieves consistent dosing accuracy within 2% repeatability. Its robust design ensures steady operation across a full flow range of 0-5 LPH and up to 7 bar discharge pressure, making it ideal for demanding chemical dosing applications.

User-Oriented Features for Seamless Operation

This pump incorporates a manual priming valve for easy startup, an intuitive LED indicator for power and dosing status, and an ergonomic manual stroke length adjustment for precise control. With quick, tool-free diaphragm replacement and all accessories included, installation and maintenance are straightforward.

Built for Tough Environments

Encased in IP65-rated weatherproof housing, the SEKO pump is protected against dust and water, ensuring reliability in harsh settings like water treatment facilities and chemical plants. Corrosion-resistant materials such as polypropylene, PTFE, and ceramic components further enhance longevity.

FAQ's of SEKO Solenoid Dosing Pump:

Q: How is the SEKO Solenoid Dosing Pump installed and where can it be mounted?

A: The pump is designed for easy wall or surface mounting and comes with a complete installation kit, including all necessary accessories. Its compact dimensions and lightweight (approx. 2.1 kg) make it suitable for various settings such as water treatment plants, RO systems, ETPs/STPs, and chemical dosing stations.Q: What level of dosing accuracy does the SEKO Solenoid Dosing Pump offer, and how does it achieve it?

A: The pump delivers high dosing precision with 2% repeatability, facilitated by an electromagnetic solenoid drive and adjustable stroke length. The integrated LED display further assists in monitoring both power and dosing operations for enhanced control.Q: When should you use the manual priming function on this pump?

A: Manual priming, accomplished via the integrated priming valve, should be performed during initial installation or after any maintenance that introduces air into the lines. This ensures the pump is filled with fluid and prevents air lock during startup.Q: What are the main benefits of the tool-free diaphragm replacement feature?

A: Tool-free diaphragm replacement greatly simplifies routine maintenance, reducing downtime and allowing quick servicing without specialized skills or equipment. This feature helps maintain reliable operation and prolongs the pump's service life.Q: How does the SEKO pump resist corrosion and environmental stress?

A: Constructed with a polypropylene pump head, PTFE diaphragm, Viton/EPDM seals, and a ceramic ball, the SEKO pump is built for excellent chemical resistance. Its IP65 weatherproof enclosure shields it from dust, splashes, and harsh operational environments.Q: What types of chemicals and applications is this pump suitable for?

A: The SEKO Solenoid Dosing Pump is ideal for precise chemical dosing needs such as water treatment, reverse osmosis plants, effluent and sewage treatment facilities, and other industrial applications needing adjustable dosing and resistance to aggressive substances.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dosing Pumps Category

SEKO Motor Driven Dosing Pump

Price 45000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Chemical Dosing

Material : Polypropylene, PVDF, SS316

Power : Other, 45W to 60W

Meta Dosing Pump

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Water, Oil Well, Food

Material : Stainless Steel, PP, Teflon

Power : Electric

Color : Orange

Solenoid Diaphragm Dosing Pump

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Chemical Dosing

Material : Stainless Steel, PP, Teflon

Power : Electric

Color : Orange

Dosing Pump

Price 40000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Metal, Plastic

Color : Multicolor

Send Inquiry

Send Inquiry Call Me Free

Call Me Free