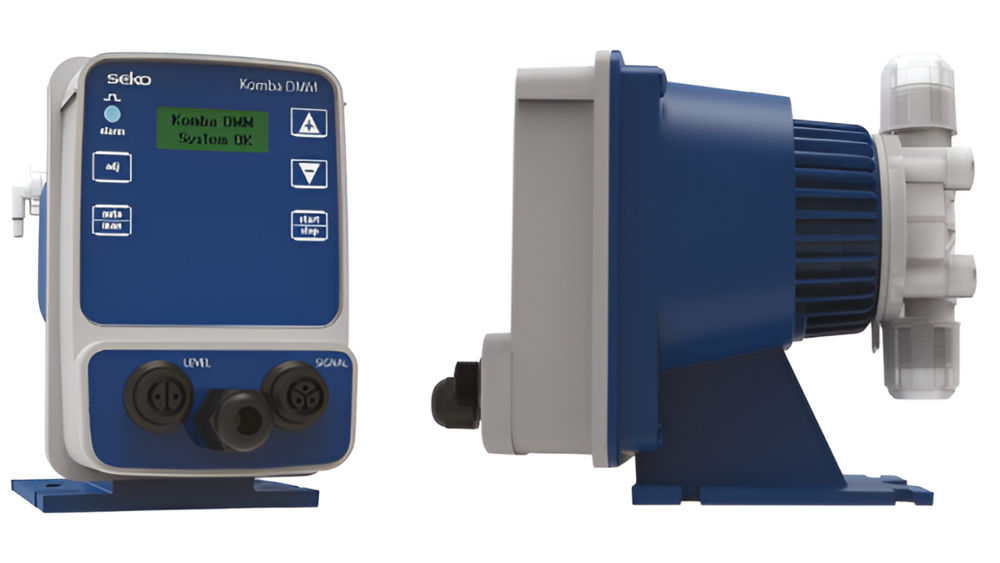

SEKO Motor Driven Dosing Pump

SEKO Motor Driven Dosing Pump Specification

- Frequency

- 50/60Hz

- Features

- Corrosion-resistant, compact design, integrated safety mechanisms

- Inlet/Outlet

- 1/2 BSP

- Noise Level

- <65 dB

- Mounting Type

- Wall or floor mount

- Max Suction

- Up to 2 meters

- Theory

- Reciprocating Pump

- Working Temperature

- 0C to 50C

- Voltage

- 220/240V, 50/60 Hz

- Speed

- Adjustable via control system

- Head Size

- Up to 10 meters

- Discharge Pressure

- Max 10 bar

- Control System

- Manual or automatic (digital control options)

- Flow Rate

- 0.5 to 25 L/h

- Caliber

- DN10

- Material

- Polypropylene, PVDF, SS316

- Structure

- Diaphragm Motor Driven

- Power

- 45W to 60W

- Standard

- CE certified

- Fuel Type

- Electric

- Pressure

- 0 to 10 bar

- Usage

- Chemical Dosing

- Application

- Water Treatment, Chemical Injection

- Suction Type

- Automatic

- Seals Type

- PTFE and EPDM options available

- Priming

- Self-priming

- Pump Type

- Motor Driven Dosing Pump

- Capacity

- Up to 25 L/h

- Motor Type

- Asynchronous Motor

- Diaphragm Material

- PTFE Coated

- Electrical Protection

- Thermal Overload

- Stroke Adjustment

- 0-100% Manually or Electronically

- Weight

- Approx. 12 kg

- Enclosure Protection

- IP55

- Maximum Ambient Humidity

- 90% RH (non-condensing)

- Connection Type

- Threaded/Flanged Optional

- Maximum Viscosity

- Up to 2000 cps

SEKO Motor Driven Dosing Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

About SEKO Motor Driven Dosing Pump

Typical Applications:

- Water Treatment: For precise chemical dosing to adjust pH, disinfect water, or add other chemicals needed for treatment processes.

- Agriculture: Used for controlled application of fertilizers, pesticides, or herbicides to ensure effective crop management.

- Chemical Processing: Enables accurate and consistent injection of chemicals, additives, or reagents in various production processes.

- Food Production: Used in the controlled dosing of food-grade ingredients, such as preservatives or flavorings, to ensure product consistency and safety.

Reliable Performance in Challenging Environments

With enclosure protection rated at IP55 and robust construction from high-quality materials such as polypropylene, PVDF, and SS316, the SEKO Motor Driven Dosing Pump is designed for longevity and dependability. It smoothly handles harsh industrial settings, ensuring continuous operation even in the presence of high humidity levels, making it ideal for chemical dosing and water treatment applications.

Enhanced Flexibility and Control

Stroke adjustment can be performed manually or electronically, from 0 to 100%, and speed can be modulated via a digital control system. This flexibility allows precise control over dosing requirements to suit varying process demands. The pump is self-priming, with automatic suction, enabling easy installation in wall or floor mount configurations. Connections are available in threaded or flanged types for greater compatibility.

Advanced Safety and Compliance

Integrated thermal overload protection safeguards the motor against overheating, ensuring consistent and safe operation. Both PTFE and EPDM seal options are available to suit specific chemical compatibility needs. The pump is CE certified, reflecting its adherence to stringent European standards and reassuring users of its quality and reliability in demanding chemical environments.

FAQs of SEKO Motor Driven Dosing Pump:

Q: How is the stroke volume of the SEKO Motor Driven Dosing Pump adjusted?

A: The stroke volume can be adjusted from 0 to 100% either manually using a control knob or electronically via a digital control system, allowing for precise customization of dosing rates to match process requirements.Q: What types of chemicals and viscosities can this pump handle?

A: Thanks to its corrosion-resistant construction and PTFE-coated diaphragm, the pump can handle a wide range of chemicals, including aggressive and viscous fluids, with viscosities up to 2000 cps, making it suitable for water treatment and chemical injection tasks.Q: When is the SEKO dosing pump best utilized?

A: This dosing pump is ideal for applications requiring accurate chemical metering, such as water treatment facilities, industrial chemical dosing systems, and other processes where precise control of liquid addition is critical.Q: Where can the SEKO Motor Driven Dosing Pump be installed?

A: It is designed for flexible installation, supporting both wall and floor mounting options. Its compact and robust design makes it suitable for indoor industrial environments, especially where space and ambient conditions demand protection and durability.Q: What are the main benefits of using this dosing pump?

A: Key benefits include reliable and consistent chemical dosing, corrosion resistance, self-priming capability, integrated safety mechanisms, and ease of installation with both threaded and flanged connection options. Its compliance with CE standards ensures quality and safety.Q: How does the pump ensure operational safety during prolonged use?

A: It features built-in thermal overload protection to prevent overheating, alongside durable seals and a weather-protected enclosure, minimizing maintenance needs and safeguarding against unexpected failures during continuous operation.Q: What connection and sealing options are available for the pump?

A: Users can choose between threaded or flanged connections for the inlet/outlet according to their pipeline setup. Seal options include PTFE and EPDM, catering to diverse chemical compatibility requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dosing Pumps Category

SEKO Solenoid Dosing Pump

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Other, 25W

Material : PP (Polypropylene) pump head, Viton/EPDM seals, ceramic ball

Seals Type : PTFE diaphragm

Usage : Other, Chemical dosing, water treatment

Meta Dosing Pump

Price 45000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Electric

Material : Stainless Steel, PP, Teflon

Seals Type : Sealed

Usage : Water, Oil Well, Food

Solenoid Diaphragm Dosing Pump

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Electric

Material : Stainless Steel, PP, Teflon

Seals Type : Sealed

Usage : Chemical Dosing

Solenoid Driven Dosing Pumps

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Electric

Material : Stainless Steel, PP, Teflon

Seals Type : Sealed

Usage : Industrial

Send Inquiry

Send Inquiry Call Me Free

Call Me Free