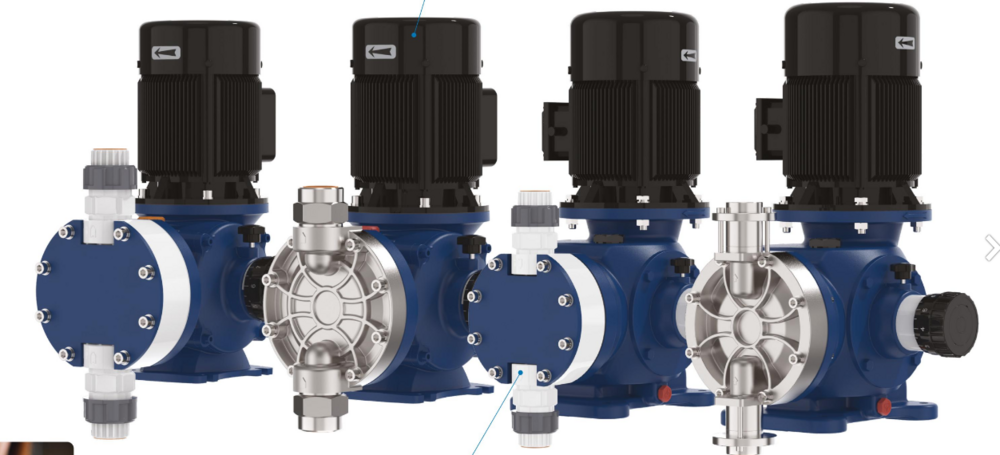

SEKO Electric Motorized Dosing Pump

SEKO Electric Motorized Dosing Pump Specification

- Features

- Corrosion resistant, compact design, easy maintenance

- Working Temperature

- 0C to 40C

- Head Size

- up to 10 Bar

- Inlet/Outlet

- PVC / PP 1/2 BSP

- Noise Level

- Low

- Frequency

- 50Hz

- Max Suction

- 2 meters

- Control System

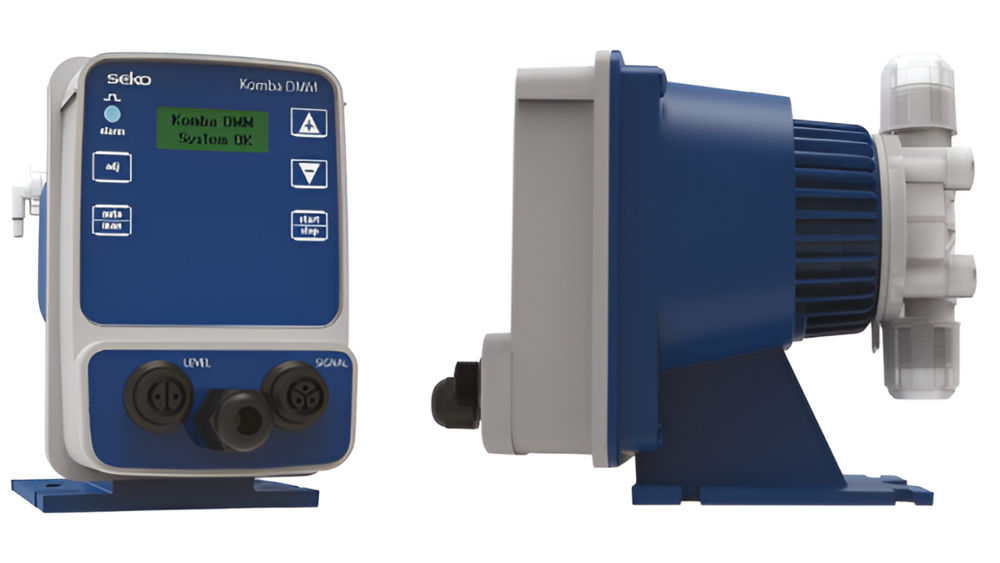

- Manual or digital microprocessor based

- Speed

- Variable

- Voltage

- 220V / 50Hz

- Theory

- Diaphragm Dosing Pump

- Mounting Type

- Wall/Panel/Foot Mount

- Discharge Pressure

- Up to 10 Bar

- Flow Rate

- 0.5 100 LPH (Liters Per Hour)

- Caliber

- Standard

- Material

- PP/PVC/SS316/PVDF options

- Structure

- Diaphragm type motorized pump

- Power

- up to 60W

- Standard

- CE marked / ISO approved

- Fuel Type

- Electric

- Pressure

- up to 10 Bar

- Usage

- Chemical Dosing

- Application

- Water treatment, Industrial process, Chemical dosing

- Suction Type

- Self-priming

- Seals Type

- EPDM / Viton / PTFE

- Priming

- Automatic

- Pump Type

- Motorized dosing pump

- Capacity

- Adjustable (0.5 100 LPH)

- Connection Type

- Threaded / Flanged

- Display

- LCD/LED (on select models)

- Range of Stroke Length

- Adjustable

- Accuracy

- ±2%

- Protection Class

- IP65

- Lubrication

- Maintenance free

- Weight

- 5-10 kg (depending on model)

- Drive Type

- Electric motor driven

SEKO Electric Motorized Dosing Pump Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 3 Week

- Main Domestic Market

- All India

About SEKO Electric Motorized Dosing Pump

Benefits:

- Enhanced Operational Efficiency: Helps streamline fluid management processes, reducing material waste and improving system performance.

- Reduced Downtime: With minimal maintenance requirements and durable design, the pump operates smoothly, contributing to reduced production interruptions.

- Cost-Effective: Its energy efficiency and low maintenance needs make it a cost-effective choice for both small-scale and large-scale operations.

Optimized for Industrial Versatility

Engineered for a broad spectrum of chemical dosing applications, the SEKO motorized dosing pump delivers consistent performance in both water treatment and industrial processes. Its compatibility with aggressive chemicals, wide material selection, and variable flow capacity ensure adaptability for changing operational needs.

Ease of Use and Maintenance

The pump incorporates intuitive controls, with select models offering LCD/LED displays for straightforward operation. As a maintenance-free unit with self-priming and automatic priming functions, it reduces downtime and minimizes servicing requirements, making it user-friendly for operators.

Safety and International Compliance

With an IP65 protection class, CE marking, and ISO approval, this pump emphasizes operator safety, environmental protection, and adherence to international quality standards. Its robust design, low noise operation, and diverse mounting configurations further enhance workplace flexibility and safety.

FAQ's of SEKO Electric Motorized Dosing Pump:

Q: How does the SEKO dosing pump ensure accurate chemical dispensing?

A: The SEKO electric motorized dosing pump utilizes an adjustable diaphragm mechanism and precision electric drive to deliver a flow rate accuracy of 2%. Users can fine-tune capacity (0.5 - 100 LPH) and stroke length to closely match the required dosing parameters, ensuring precise and reliable chemical delivery.Q: What chemicals and fluids can this pump handle safely?

A: Thanks to its material options-PP, PVC, SS316, and PVDF-and EPDM / Viton / PTFE seals, the pump is suitable for a wide range of chemicals, including corrosive acids, alkalis, and water treatment agents. Always verify chemical compatibility with the selected materials for optimal safety and performance.Q: Where can the SEKO dosing pump be installed and used?

A: Designed with flexible mounting (wall, panel, or foot), this dosing pump is suitable for use in water treatment facilities, industrial process plants, and chemical dosing systems. Its IP65 protection rating and corrosion-resistant construction allow installation in various demanding environmental conditions.Q: What are the primary benefits of using a motorized dosing pump?

A: A motorized dosing pump offers precise adjustability, consistent dosing rates, low noise operation, and minimal routine maintenance. These features translate into reduced operational costs, enhanced process control, and improved worker safety compared to traditional manual pumps.Q: How should the pump be maintained during operation?

A: The SEKO dosing pump features maintenance-free lubrication and automatic priming, reducing the need for frequent operator intervention. Regular inspection of seals and connections is recommended to ensure continued leak-free performance and longevity.Q: When should I use the manual versus the digital microprocessor control system?

A: Manual control is ideal for straightforward dosing tasks or smaller systems, whereas the digital microprocessor-based control is better for complex operations needing precise dosing profiles, remote monitoring, or integration with automation systems.Q: What is the process for installing the SEKO dosing pump?

A: Installation involves selecting a suitable mounting type, connecting the threaded or flanged inlets and outlets, ensuring electrical connections to 220V/50Hz power, and configuring the control system (manual or digital). Always follow manufacturer guidelines for safe and effective installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dosing Pumps Category

SEKO Solenoid Dosing Pump

Price 30000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Chemical dosing, water treatment

Material : PP (Polypropylene) pump head, Viton/EPDM seals, ceramic ball

Seals Type : PTFE diaphragm

Power : Other, 25W

SEKO Metering Dosing Pumps

Price 20000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Other, Chemical Dosing

Material : PVDF / Polypropylene / PVC / SS316

Seals Type : PTFE/Teflon Diaphragm

Power : Other, 20W

Dosing Pump

Price 40000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Metal, Plastic

Industrial Dosing Pump

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Mild steel

Seals Type : Sealed

Power : Electric

Send Inquiry

Send Inquiry