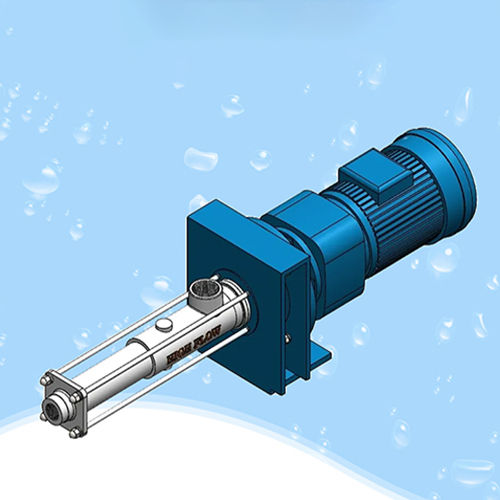

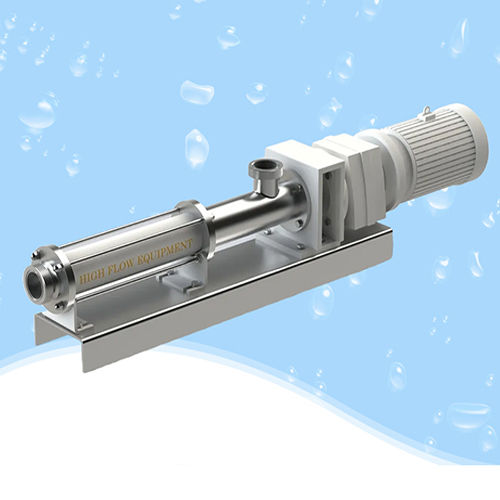

Hygenic food & Beverage pump

Hygenic food & Beverage pump Specification

- Usage

- Industrial

- Material

- Metal

- Size

- Various available

- Pressure

- High Pressure

- Color

- Silver, White

Hygenic food & Beverage pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Hygenic food & Beverage pump

Hygienic food and beverage screw pumps are specifically engineered to meet the rigorous standards of the food and beverage industry. These pumps ensure reliable and efficient fluid transfer while maintaining the highest levels of hygiene and product integrity. Constructed from food-grade materials such as stainless steel, their design features smooth surfaces that minimize bacterial growth and facilitate easy cleaning.

These pumps excel in gently handling various products, utilizing a positive displacement mechanism that is ideal for shear-sensitive items like creams, sauces, and juices. This gentle transfer process preserves the texture and quality of the fluids being pumped. Many hygienic screw pumps are self-priming, enhancing usability and reducing contamination risks during startup.

FAQ for Hygenic food & Beverage pump

Q. How do hygienic screw pumps maintain product integrity?

A. The positive displacement mechanism allows for gentle handling of fluids, reducing shear forces and preventing damage to sensitive products like creams and sauces, thereby preserving their texture and quality.

Q. Are these pumps compliant with food safety regulations?

A. Yes, many hygienic screw pumps comply with FDA regulations and 3A sanitary standards, ensuring they are safe for food contact and suitable for use in food processing.

Q. What are the common applications for hygienic screw pumps?

A. These pumps are commonly used in applications such as dairy processing, beverage production, sauce and dressing handling, and confectionery manufacturing.

Q. Can these pumps handle products with varying viscosities?

A. Yes, hygienic screw pumps are highly versatile and can manage products with a wide range of viscosities, from thin liquids to thick pastes, making them suitable for various applications in food processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Screw Pumps Category

Screw Dosing Pump

Price 65000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Cast Iron

Color : Blue

Power : Electric

Single Screw Pumps

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Mild Steel

Color : Silver

Power : Electric

Screw Dosing Pump

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Metal

Color : Multicolor

Horizontal Screw Pump

Price 65000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Usage : Industrial

Material : Metal

Color : Multicolor

Send Inquiry

Send Inquiry